20. Commode

- French (Paris), portions of carcass and gilt bronze mounts, ca. 1735; finished carcass and veneer, late nineteenth or twentieth century

- By unidentified ébéniste “DF”

- White oak, maple, and fir veneered with tulipwood, kingwood, amaranth, and other unidentified woods; gilt bronze mounts; brass and iron lock; brèche d’Alep top

- H: 2 ft. 10 1/4 in., W: 5 ft. 1 1/4 in., D: 2 ft. 1 in. (87 × 155.5 × 63.5 cm)

- 76.DA.15

Description

This commode contains two drawers with functioning locks. Exhibiting a serpentine profile along the front and side panels, the rectangular case is supported by four legs and surmounted by a brèche d’Alep marble top with a molded edge.

Cast and chased gilt bronze chutes embellish the front corners, running the length of the sinuous front legs and terminating in sabots (fig. 20-1). These appear as continuous floral garlands coiffed with birds perched on leafy C-scrolls. The back legs terminate in sabots like those seen on front but take a heavier, multisided shape. Other mounts include two pairs of drawer pulls and two escutcheons in a transitional, naturalistic style seen on the drawer fronts. The apron mount features a stylized shell motif flanked on either side by C-scrolls and acanthus leaves (fig. 20-2). A continuous gilt bronze frame mount surrounds the drawers, with a similar mount used on each side of the commode. Last, a vertical mount of alternating C-shaped and foliate motifs is set on either side.

The visible surfaces of the commode’s white oak frame are entirely veneered with contrasting tulipwood, kingwood, amaranth, and three other unidentified woods. The marquetry is distinguished by a variety of abstract forms including scrolls and rocailles that extend across the drawer fronts and frame the hardware. Although the central motif on the commode’s front is irregular, the seemingly asymmetrical designs that flank it are mirror images. On the side panels, the gilt bronze frame mounts each contain a marquetry shell.

Marks

Stamped “DF” on the top of the front left stile (fig. 20-3). A partially defaced paper label on the back is printed, “(H)oult’s Ltd. / (Dep)ositories / (?)E306(9?).” “E1649” is written in chalk across the back of the carcass. Underneath the carcass near the front is an inscription in pencil that reads, “fond derrière.”

Figure 20-3

Figure 20-3Commentary

The commode is stamped with the partly obliterated initials “DF”; however, technical analysis indicates that while some elements of the carcass and the majority of the gilt bronze mounts are original to the eighteenth century, much of it has been significantly altered. The current appearance of the commode must be the result of one or more restoration campaigns, with the piece being completely reveneered in the late nineteenth or twentieth century (see “Technical Description” below).

The monogrammatic stamp “DF” is found on a small group of case furniture, mostly commodes, sharing characteristics of style, decoration, and construction. These pieces all date from the second quarter of the eighteenth century, most of them are veneered with Asian or European lacquer, and many of them have mounts of the same model.1 For these reasons it is assumed that this group is by one maker, and it is now generally agreed that the stamp “DF” probably stands for Jean Desforges (active ca. 1730–after 1757), a member of a family of Parisian ébénistes working in the first half of the eighteenth century.2 According to Calin Demetrescu, the signed initials “DF” that are found consistently in contemporary documents concerning Denis, Michel, and Jean Desforges support the assumption that those initials were used by the family as a standard identification that was transferred from father to son; in addition, the monogram “DF” was used by this family and principally by Jean, whose dates correspond with the style of the group of furniture stamped “DF.” However, this identification is not certain; it remains unclear exactly what role this maker may have had in the production of the pieces bearing this stamp. Compounding the uncertainty is the fact that the record of the registration of masters was not kept between 1693 and 1735, and no ébéniste named Desforges is registered between 1735 and 1750.3

The monogram “DF” appears more than once on furniture bearing the stamp of other ébénistes. An Asian lacquer commode stamped “DF” is also stamped “B.V.R.B.,” for Bernard II van Risenburgh. It is assumed that the latter made the carcass.4 One of a pair of Asian lacquer commodes bears the stamp “DF” and the other that of Adrien Delorme.5 Another commode bears the stamps of both Antoine and Mathieu Criaerd, as well as the “DF” mark.6 It has been suggested by Dominique Augarde that several other pieces bearing Criaerd’s stamp are so close to the style associated with the “DF” group that the two ébénistes must have collaborated more closely than was normally the case.7 It is possible that the ébéniste Jean Desforges stamped pieces made by other craftsmen either as a repairer or as a marchand-ébéniste.8

Of the pieces marked “DF” or attributed to this group, the Museum’s commode is the only piece known that is entirely veneered with wood marquetry; no other commode from this group is of the same form. While the serpentine profile of the front is typical of pieces from this group, the sides have a more pronounced S-curve and the back corners splay out wider than the front and are unusually heavy in design. The form of this piece has similarities with commodes in the Régence and early Rococo styles, before the more standard gracefully proportioned shape of the Rococo was widely adopted.9 These characteristics indicate that the Museum’s commode in its original form would date from the beginning of the “DF” group, around 1735.10

The majority of the mounts seem to date from the same period (see “Technical Description” below). The original apron mount seems to have been replaced with the current mount; it does not follow the lower profile of the carcass and is of lesser quality than the other mounts on the piece (see fig. 20-2). There is only one other known commode, called the Strauss commode, with the same mounts. It was published in 1911 and is not known to be stamped.11 The corner, feet mounts, and two keyhole escutcheons are of the same model as those found on the Museum’s commode. The framed panel on the front is of Asian lacquer, with the surrounding areas veneered with wood. This is a characteristic of all the “DF” commodes, with Asian lacquer restricted to the framed panels at the front and sides.

Although the present wood marquetry appears to date to the late nineteenth or twentieth century, similar patterns are found on other pieces made between 1730 and 1750. An unstamped commode made around 1750 with a very similarly designed marquetry cartouche on the front was sold in Paris in 1989.12 The pattern of the cartouche on the front and sides of the Museum’s commode is also very similar to that found on a secrétaire stamped “B.V.R.B.,” for Bernard II van Risenburgh, that sold from the Polès Collection in 1927.13 Other pieces with marquetry of similar design are known, most of which are stamped or attributed to Van Risenburgh.14

As for what preceded the late nineteenth- or twentieth-century veneer, it is highly likely that the commode was originally veneered with Asian or European lacquer. As stated above, the Museum’s commode is the only piece stamped or attributed to “DF” that is entirely veneered in wood. Although there is no physical evidence of the possible original lacquer veneer, if this commode is part of the “DF” group, then it is likely that it would have featured Asian or European lacquer like many in the group.

Provenance

Mrs. S. Shrigley-Feigl (Cragg Hall, Wray, Lancaster, England), sold to Alexander & Berendt Ltd.;15 –1976: Alexander & Berendt Ltd. (London, England), sold to the J. Paul Getty Museum, 1976.

Bibliography

, 12, no. 25; , 67, fig. 7; , vol. 2, 377, ill.; , 25, no. 25; , vol. 2, 377, ill.; , 14, no. 25.

- G.W.

Technical Description

The carcass of the commode is made primarily of white oak. The four corner posts run from the floor to the top of the case and are formed of single blocks of wood. The core of each of the side panels is made of two boards, butt joined, with their grain running horizontally, attached to the front and rear posts with tongue-and-groove joints. The exaggerated curves of the sides required extra thickness to be added to the panels; this was accomplished by gluing several boards with vertically oriented grain to the exterior of the sides at the front and rear and also gluing a wide, vertically oriented board (with ogee molded edges) to the inside face of each side near the middle. At the top and bottom, the side panels have tenons that fit into mortises cut into the case rails above and below.

The case back is made using an unusual five-sectioned frame-and-panel construction (fig. 20-4). The horizontal rails attach directly to the rear legs with mortise-and-tenon joints. The narrow upper rail is unpinned, while the wider rail at the bottom is pinned. The vertical medial stiles are mortise and tenoned to the upper rail with single pins but to the lower rail with double pins. The five equally sized panels of the back are each made of a single board, rabbeted on the interior edges, with the grain of the wood running vertically.

The case top is a bipartite frame-and-panel assembly with equally sized panels, each made from two butt-joined boards arranged with the grain running from side to side; these are also rabbeted on their interior edges (fig. 20-5). The side rails are attached to the corner posts with open-faced dovetails; the dovetails for the front and rear rails are unusual in-line double dovetails (fig. 20-6). The rear rail of the top overlaps the case back assembly but is not joined to it except with glue. The medial rail is joined at front and back with double-pinned mortise-and-tenon joints.

Figure 20-6

Figure 20-6The case bottom and the dustboard (separating the two drawers) are each a single frame-and-panel construction without rear rails (fig. 20-7). The ends of the front rails are set into dadoes in the corner posts. The side rails of the case bottom run at an angle between the corner posts and are attached with sliding dovetails whose mortises run through the entire thickness of the posts. The very large bottom panel is rectangular and does not reach all the way out to the side rails. The triangular spaces between the 2-in.-wide side rails and the case-bottom panel are filled with triangular blocks of oak that are attached to the rails with tongue-and-groove joints. This is a very peculiar construction that is atypical of eighteenth-century Parisian cabinetmaking. The case-bottom panel itself is made of seven butt-joined boards of irregular width whose grain runs from front to back; all edges are rabbeted along the lower edges, and the panel is supported at the rear in a groove cut into the lower rail of the case back.

At the level of the dustboard, the side rails supporting the panel are made of single triangular blocks that are mortise and tenoned into the front rail and set into dadoes in the rear posts. In contrast to the case bottom, the large single panel is made of two boards with their grain oriented from side to side; the front and side edges are rabbeted, while the rear edge, which is entirely unsupported, is not.

The four internal drawer supports are each made of a single strip of oak, glued directly to the edges of the bottom panel and dustboard panel, respectively (fig. 20-8). Adjacent to each drawer support strip, two additional strips of oak are stacked, glued, and nailed to the side rails, to serve as drawer guides. There are no separate kickers installed in the case to prevent the drawers from tipping forward when opened.

To form the curved lower edge of the case front and sides, numerous short blocks of oak, maple, and fir have simply been glued to the underside of the rails and then sawn and carved to shape in order to create the desired profile.

The curved drawer fronts are made in a five-layered laminated construction, stacked and glued from front to back. Each layer is approximately 2.3 cm thick and is the full height of the drawer. The upper edges of both drawer fronts are veneered with purpleheart. The sides and backs of the drawers are made of single boards of oak and have slightly rounded top edges; they are assembled using standard through-dovetails at the rear and half-blind dovetails at the front. The front dovetails are partially hidden by added strips of oak glued over them to extend the drawer fronts. The front leg posts have been rebated along their front edges to accommodate these drawer front extensions. The drawer bottoms are each made of five thin boards, butt joined, with the grain running front to back; four of these are quite wide, while the fifth, at one end, is narrow. The boards of the drawer bottoms are all neatly quartersawn; all other panels in the commode are plain sawn. The bottoms are set into rabbets in the lower edge of the drawer fronts and backs and fastened with nails. At the sides, long thin strips of oak have been glued to the bottom edges of the drawer sides. These have been rabbeted to form grooves that capture the edges of the drawer bottom panels. It is not entirely clear if this is the original construction or a repair.

The commode is veneered with a marquetry decoration made of at least six different species of wood. Study of the wood under the stereomicroscope strongly suggests the presence of tulipwood, kingwood, and amaranth. Three other woods could not be securely identified; two are dark in tone, and the third is light. These three appear to be tropical species that are not part of the usual palette of woods used by eighteenth-century French cabinetmakers.

The condition of the marquetry decoration is extremely good, with no obvious replacement on the front and right side panels of figurative marquetry. The left side panel, however, was extensively restored in 1977, and there are large elements that appear to be recent replacements, the wood being of a lighter color and almost certainly not of the appropriate species. The diagonally oriented veneer surrounding the ornamental panels is of kingwood, apparently with large areas of replacement, particularly on the sides.

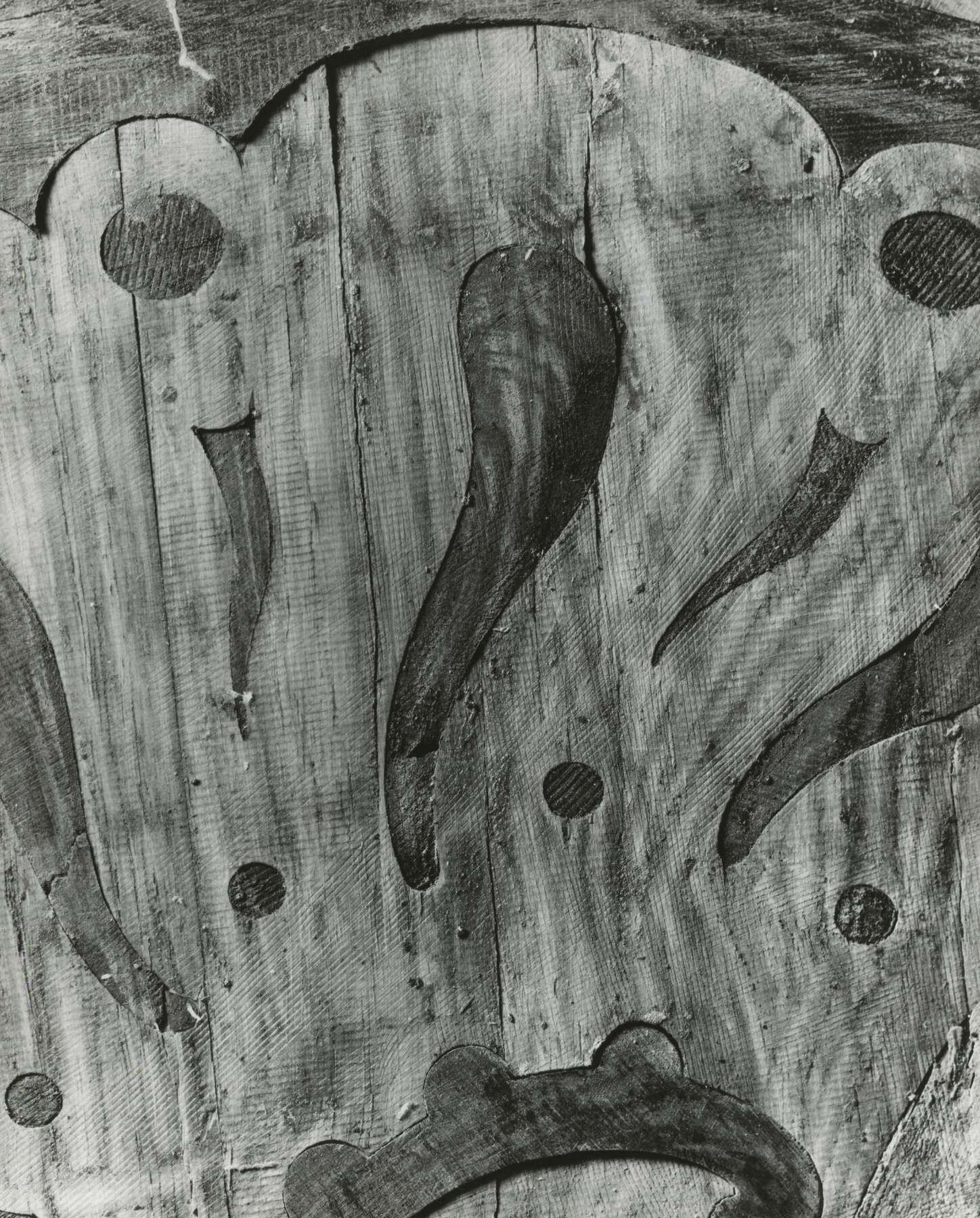

A number of lines of evidence suggest that this commode has been massively restored and altered. It appears, for instance, that nearly the entire commode has been reveneered. Three kingwood elements on the left side show distinct, parallel, and regularly spaced markings that are typical of mechanical veneer saw marks (fig. 20-9). These saw marks should have been removed during the scraping and sanding of the marquetry when it was originally made, but in these areas the marks have survived. In addition, photographs taken during the 1977 restoration of the left side marquetry clearly reveal that such mechanical saw marks appear on the reverse of virtually every element within the decorative marquetry panels (fig. 20-10). Although mechanical saws had been invented many centuries before the manufacture of this commode,16 it appears that such saws were not used to cut veneer in France until the beginning of the nineteenth century. The detailed descriptions of furniture production given in Roubo refer only to the sawing of veneers by hand.17 Furthermore, the earliest verified French patent for a veneer-cutting saw is that of Jean-Baptiste-Marie Albert Cochot, registered in 1814,18 and the first known English patent for such a device appears to be in 1842 by Gregson.19

Figure 20-9

Figure 20-9 Figure 20-10

Figure 20-10In addition to the evidence of the veneer sawing, a close examination of the marquetry decoration shows that the entire marquetry was cut with a fretsaw using a technique known as “piece by piece,” which, as the name suggests, means that each element of the marquetry was cut individually before being assembled and glued on the solid wood carcass. This marquetry technique was in common use from the nineteenth century, but there is no documented example of this technique being used prior to that time.

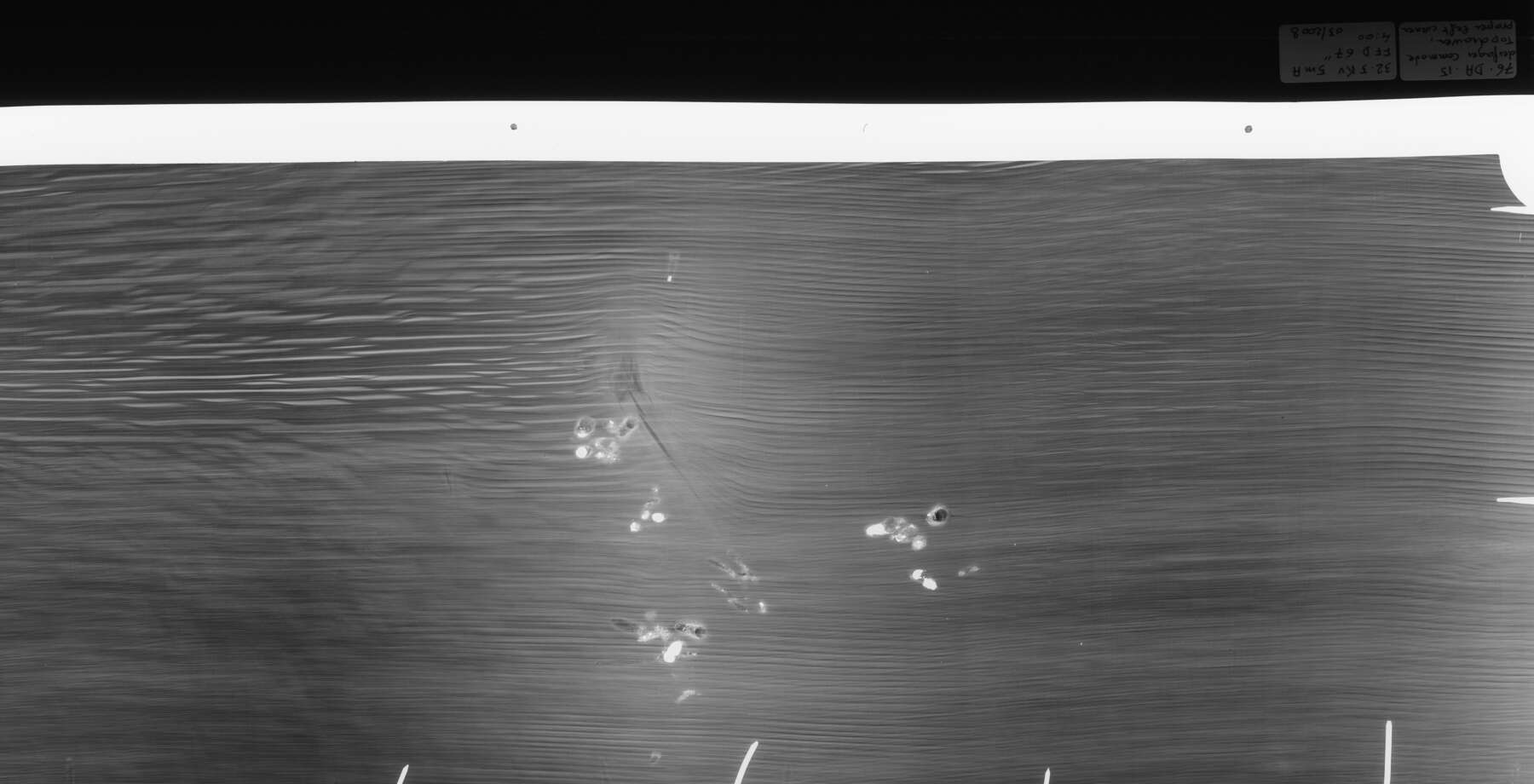

Yet another clear indicator that the decorative marquetry panels have been replaced can be seen in X-radiographs of the drawer fronts. These images (fig. 20-11) clearly show that the existing handles have been mounted to the drawers in several slightly different positions throughout the history of the piece; however, only the most recent set of screw holes are currently visible. Previous generations of screw holes have been covered by the existing marquetry, confirming that the latter is a relatively recent addition. As discussed in “Commentary” above, it seems likely that the areas now covered with decorative marquetry in wood once contained panels of Asian lacquer, though no supporting physical evidence for this could be found.

Figure 20-11

Figure 20-11The diagonally oriented kingwood veneer that covers the legs and frames the marquetry panels appears also to have been heavily restored. A careful examination of the veneer reveals that two distinct types of kingwood veneer are prevalent on the carcass. The first is very precisely quartersawn veneer; this type is easily identifiable by eye by virtue of its ubiquitous light-colored rays, which, upon quartersawing, appear as tiny bright streaks running perpendicular to the grain direction (fig. 20-12). This type of veneer is predominant on the front surfaces of the legs and the carcass. In certain areas, however, large sections have been replaced with a second type of kingwood veneer that is mostly flat sawn. This second type of veneer lacks the ray “streaks” and generally exhibits dark stripes in the grain that are more widely spaced than in the quartersawn variety (fig. 20-13). The kingwood in the replaced areas of diagonal veneer on the carcass bears a strong resemblance to that used in the decorative marquetry panels, suggesting that they may be contemporary.

Figure 20-12

Figure 20-12 Figure 20-13

Figure 20-13The pattern of veneer replacements on the front of the carcass is suggestive of further alterations to the structure of the commode. Many of the replacements are concentrated around the joints between the front rails and the legs; this includes the entire surfaces of both front corner brackets. This pattern is consistent with a previous complete disassembly of the carcass (more evidence of which below). Closer inspection of the corner brackets (both on the front and on the sides) reveals that they are made from a variety of woods, including, apparently, fir and maple. This suggests that the brackets are elaborated replacements, the originals most likely being simple curved shapes similar to those still found on the back of the commode (see fig. 20-4) and also to those found on the Strauss commode.

The peripheral kingwood veneer on the case sides appears to be entirely of the flat-sawn variety, suggesting that it has been entirely replaced. Further veneer replacements occur at the center of the top rail and on the central apron, both of which have been entirely re-covered with flat-sawn veneer. Examination of the top rail reveals that the front edge of the substrate has been built out behind the veneer with a thin strip of oak, presumably to make it conform better to the profile of the drawer fronts. The replaced veneer in this area suggests that this was done as part of a restoration campaign. The complete replacement of veneer on the elaborately shaped apron suggests that this element, like the corner brackets, may also be an elaborated replacement for a simpler original apron, perhaps similar to the one on the Strauss commode. Support for this conjecture lies in the highly unusual V-shaped block construction of the apron and the fact that the bow-shaped support block (for which there is no known precedent) is exactly 1 in. thick, suggesting the use of an English standard-thickness plank (see fig. 20-7).

Methodical measurement of structural elements in the commode proves to be quite revealing. A very large number of individual pieces of oak in the construction have been cut to dimensions corresponding to Imperial units (inches) used in the United States and the United Kingdom to this day but not used in eighteenth-century France. While one might expect some measurements to conform to Imperial units by pure chance, the prevalence of such measurements on this commode clearly exceeds chance by a substantial margin and therefore provides a strong indication that large sections of the commode were fabricated in the United States or the United Kingdom (the latter is more likely, as evidenced below). To give some examples, the vertical stiles of the case back are each exactly 2 3/4 in. wide, and they are spaced exactly 8 in. apart; the upper rail is exactly 1 3/4 in. wide, and the lower rail is exactly 2 3/4 in. wide (see fig. 20-4). Furthermore, all of the holes for the wooden pins in the mortise-and-tenon joints are perfectly round and appear to have been drilled with a 5/16 in. bit. All of this is strong evidence that the entire case back has been replaced.

The evidence on the case top is less clear (see fig. 20-5). The rear rail is exactly 2 1/4 in. wide; however, the medial rail is slightly less than 5 in. Arguing for the originality of parts of the top, the pins for the medial rail’s tenons are oblong and slightly smaller than those on the back; in their smaller dimension they are almost exactly 1/4 pouce, or “Paris inch,” of the eighteenth century. On the other hand, two characteristics of the top’s panels arouse suspicion. The first is the presence of ersatz “wormholes” in both panels. There are twenty-one holes spread across both panels that have the outward appearance of being flight holes of wood-boring insects. Closer inspection and measurement readily shows that these holes have been drilled with a 1/32-in. drill bit, and many of the holes go straight through the panels. The only apparent reason for someone to have made these holes is to create the illusion of age in young wood. Thus the presence of these artificial wormholes suggests strongly that the panels, at least, have been replaced. Numerous artificial wormholes also appear on the panels and rails of the case back, and again, many are drilled straight through from front to back. On the case back, the drill bit used was 1/16 in. in diameter.

In addition to the drilled “wormholes,” the proper right panel of the case top appears to have a split in one of its boards, not an uncommon occurrence in large panels on eighteenth-century furniture. Again, however, all is not as it initially appears. The “split,” within a single board, is in fact perfectly straight and has edges that are perfectly perpendicular to the surface; that is, the split has been cut into the panel, apparently again with the intent to foster the appearance of age.

The panels of the case bottom and the drawer divider are both probably replacements. Single, undivided panels of this size appear to be without precedent in eighteenth-century Parisian work. Both are rabbeted, not chamfered, on their edges, as are the replaced panels of the back and top. The rabbet on the proper right side of the middle panel is particularly noteworthy as it appears to have been cut into the edge of the panel using a table saw. From below, the kerf of the circular blade, precisely 1/8 in. thick, can be seen and measured.

Careful measurement is also revealing with regard to the drawers. All of the dovetails at the rear corners of the drawers have been laid out using spacings that conform to Imperial units, suggesting that the drawer backs and sides are replaced. The drawer bottoms are currently held in place with wire nails; however, an additional, earlier set of nail holes exists alongside these nails. The earlier nail holes are perfectly round and retain the impression of the perfectly round nail heads. This suggests that the “original” fastenings for the drawer bottoms were also industrially produced flat-headed wire nails and thus that the drawers were assembled after about 1880 when such wire nails became common. In contrast, the dovetails at the front corners of the drawers do not conform to Imperial units. This, along with the X-ray evidence showing the multiple former locations of the handles, suggests that the substrates of the drawer fronts could be early.

The majority of the gilded bronze mounts were removed for examination and alloy analysis by X-ray fluorescence spectroscopy (XRF). The majority of the mounts appear consistent with eighteenth-century manufacture. Alloy analysis shows relatively high levels of impurities such as silver and antimony as well as moderate zinc content (17–21%) and tin levels around 1.5%, all of which are consistent with period manufacture. The exceptions are the midleg mount on the left side and the apron mount, both of which appear to be later additions. Examination of the back side of the midleg mount reveals that it is a copy or surmoulage of the corresponding mount on the right side; file marks and holes for screws on the original mount clearly appear, cast in, on the copy. The tone of the gilding on this mount is also noticeably different from that of the other mounts, and it is distinctly free of even mild surface corrosion. Interestingly, the copy was made in three sections of approximately equal length, with the center section inverted. It is not clear if this was done intentionally to give an illusion of symmetry to the copy or if it was simply the result of an error during the reproduction process, though the former seems more likely. In most respects, the alloy of this surmoulage is not dramatically different from other original mounts on the commode; however, it does contain an unusually large amount of nickel, a feature that does not appear to be common in French gilt bronze until after about 1890 and that is uncommon after the mid-twentieth century. The brass cover plate of the lock in the lower drawer shares a similarly high nickel content, suggesting a similar date range.

The other mount that appears to be a later addition is the central apron mount (see fig. 20-2). This mount has little in common stylistically with the other sculptural mounts on the commode, and the fact that the entire apron, to which it is attached, has been replaced immediately suggests that it may not be original. Alloy analysis by XRF reveals that the mount has an anomalously high zinc content in comparison to all of the other mounts, a level (approximately 28%) that does not appear at all in French mounts until after about 1860.

The commode’s marble tabletop is approximately 2.3 cm thick and is made of brèche d’Alep, a heterogeneous marble consisting of multicolored, somewhat rounded cobbles in a beige to orange sand and gravel matrix. The predominant color of the cobbles is from tan to cream, although red and even black cobbles are found as well. Many similar limestone breccias of this type occur in varying colors throughout the Mediterranean. The original Alep Breccia is from Syria. This stone, however, is thought to have been quarried in Le Tholonet, Bouches-du-Rhône, France. Although the quarry is inactive now, it had been in use since ancient times. Near the left end, the slab has been broken into five major fragments and repaired with four iron cramps.

In summary, this commode appears to retain some elements of a commode by DF dating to around 1735; however, at least one and possibly multiple restoration campaigns have significantly altered the piece since that time. Many wooden structural elements have been replaced, and some of the replacements were clearly disguised with the intent to conceal the intervention. With this degree of restoration, it is difficult to say to what extent the commode retains its original form and dimensions. Clearly the majority of the marquetry and veneer on the surface of this commode dates to the late nineteenth or twentieth century. That said, the gilt bronze mounts appear to be mostly of the period, possibly “original,” as do the substrates of the legs and possibly the substrates of the drawer fronts of the commode.

- A.H.,

- Y.C.

- and R.S.

Notes

For a list of commodes stamped “DF,” see , 178. ↩︎

See , 66–81, esp. 81. ↩︎

Paris, Archives nationales de France, Y 9323 to 9327. Pradère has argued that since there was no trace of a Jean Desforges and no trace of an ébéniste with a Christian name beginning with D and a surname beginning F, the more common method of forming a monogram, he suggests the possibility of a double surname, François Delorme-Faizelot (1691–1768), better known as François Faizelot-Delorme, which would be appropriate since he was an ébéniste who specialized in lacquer furniture. See , 177–78. However, in light of Demetrescu’s research, this hypothesis would no longer seem very plausible. ↩︎

, 178, appendix, no. 8, veneered with Chinese lacquer, formerly in the Josse Collection. , 114. Sold, Christie’s, French and Company: Magnificent French and English Furniture, November 24, 1998 (New York: Christie’s, 1998), and now in a private collection. When this commode was sold in 1998, it was discovered to be the commode of the dauphine, Marie-Theresa Rafaella, marked with the inventory number 1343. Only Pradère has published that the commode was stamped “DF” in addition to “B.V.R.B.” ↩︎

, 177, fig. 161, ex. coll. Galerie Segoura, Paris. ↩︎

Sotheby’s, Sale June 25, 1982 (London: Sotheby’s, 1982), lot 35; the citation for this auction is from Francis J. B. Watson, “Biography of the Master DF,” unpublished manuscript of National Gallery of Art Systematic Catalogue volume on French eighteenth-century furniture and decorative arts (substantially completed by 1986/87), in the curatorial files of the National Gallery of Art, Washington, DC. This auction was then published by , 74. This commode was wrongly identified as being in an auction on this date. ↩︎

See Watson, “Biography of the Master DF,” which cites undated correspondence with Jean-Dominique Augarde. Also, concerning the network between the ébénistes “DF” and Criaerd, see , 69, 81. Moreover, Demetrescu acknowledges the documentation he consulted at the Centre de Recherche Historique sur les Maîtres Ébénistes, where Augarde was a principal director. ↩︎

, 80. See also draft catalogue entries for acc. nos. 1942.9.408, a commode, and 1942.9.417 and .418, a pair of encoignures, all three stamped “DF” and attributed to Joseph Baumhauer by Watson, “Biography of the Master DF.” He, in agreement with Pradère that “DF” was not Jean Desforges, argued that it was “the Master DF” who stamped objects in his capacity as a restorer or marchand-ébéniste. ↩︎

See, e.g., cat. nos. 14 and 6 (Baumhauer and Van Risenburgh, respectively). See also . ↩︎

Pieces from the “DF” group are dated between ca. 1730 and 1755. See , 66–81. ↩︎

, pl. 17. In the collection of a Monsieur Strauss, present location unknown. ↩︎

Sold, Ader Picard Tajan, Objets d’art et de très bel ameublement, December 5, 1989 (Paris: Ader Picard Tajan, 1989), lot 152. In this catalogue the commode is attributed to Jean-Pierre Latz, an attribution doubted by Henry Hawley (note, object file of 76.DA.15, Sculpture and Decorative Arts Department, J. Paul Getty Museum). The marquetry on the commode is somewhat similar in character to the marquetry found on a long case clock stamped “I.P.LATZ,” now at Waddesdon Manor. See , vol. 1, 84–88, cat. no. 11. ↩︎

Sold, Galerie Georges Petit, Objets d’art et de magnifique ameublement du XVIIIe siècle, June 22–24, 1927 (Paris: Galerie Georges Petit, 1927), lot 255, pl. CIV. ↩︎

See the following examples for marquetry of similar design: Advertisement by Rheims & Laurin, Burlington Magazine 110, no. 787 (October 1968), lii; Sold, Palais Galliéra, Céramique de la chine, tableaux anciens, bel ameublement du XVIIIe siècle, November 30, 1968 (Paris: Palais Galliéra, 1968), lot 266; bureau plat, stamped “B.V.R.B.,” sold, Sotheby’s, Property from the Estate of Mrs. Charles Allen, Jr., November 1, 1997 (New York: Sotheby’s, 1997), lot 106; commode, by Bernard II van Risenburgh, , 57; secrétaire en pente, probably by Bernard II van Risenburgh, sold, Sotheby’s, Rugs and Carpets, Tapestries, Clocks, Works of Art, Important French Furniture, November 24, 1972 (London: Sotheby’s, 1972), lot 83; also illustrated in , 883. ↩︎

Invoice from Alexander & Berendt, Ltd., May 13, 1976, in the files of the Sculpture and Decorative Art Department, J. Paul Getty Museum. ↩︎

, 52–53. ↩︎

, vol. 3, 799–802. ↩︎

Jean-Baptiste-Marie Albert Cochot, Mécanique propre à scier en feuilles le bois d’acajou, ou tout autre bois. Brevet d’invention de 5 ans, pris le 7 décembre 1814. Pub. T7, p. 361. INPI (Institut National de la Propriété Industrielle). ↩︎

Matthew Gregson, Cutting Veneers, “An Invention or Improvement applicable to the Sawing or Cutting of Veneers.” Patent number 9503, April 29, 1842. Both the French and English patent records have been extensively searched by Chastang on this account. ↩︎

Bibliography

- Bremer-David et al. 1993

- Bremer-David, Charissa, et al. Decorative Arts: An Illustrated Summary Catalogue of the Collections of the J. Paul Getty Museum. Malibu, CA: J. Paul Getty Museum, 1993.

- De Bellaigue 1974

- De Bellaigue, Geoffrey. The James A. de Rothschild Collection at Waddesdon Manor: Furniture, Clocks and Gilt Bronzes. 2 vols. Fribourg: Office du Livre, 1974.

- Demetrescu 1992

- Demetrescu, Calin. “D.F. un ébéniste identifié.” L’Estampille/L’Objet d’Art 262 (October 1992): 66–81.

- Demetrescu 2003

- Demetrescu, Calin. Le style Régence. Paris: Éditions de l’Amateur, 2003.

- Gruber 1996

- Gruber, Alain, ed. History of Decorative Arts. Vol. 2, Classicism and the Baroque in Europe. New York: Abbeville Press, 1996.

- Gruber 1992

- Gruber, Alain, ed. L’art décoratif en Europe. Vol. 2, Classique et baroque. Paris: Citadelles & Mazenod, 1992.

- Guérin 1911

- Guérin, Jacques. La Chinoiserie en Europe au XVIIIe siècle: Tapisseries, meubles, bronzes d’ameublement, céramiques, peintures et dessins, exposés au Musée des arts décoratifs. Paris: Librairie centrale des beaux-arts, 1911.

- Kjellberg 1989

- Kjellberg, Pierre. Le mobilier français du XVIIIe siècle: Dictionnaire des ébénistes et des menuisiers. Paris: Éditions de l’Amateur, 1989.

- Molinier 189?

- Molinier, Émile. Histoire générale des arts appliqués à l’industrie du Ve à la fin du XVIIIe siècle. Vol. 3, Le mobilier au XVIIe et au XVIIIe siècle. Paris: Librarie centrale des beaux-arts, 189?.

- Pradère 1989a

- Pradère, Alexandre. French Furniture Makers: The Art of the Ébéniste from Louis XIV to the Revolution. Malibu, CA: J. Paul Getty Museum, 1989.

- Roubo 1774

- Roubo, André Jacob. L’art du menuisier ébéniste. Paris: L. F. Delatour, 1774.

- Sassoon and Wilson 1986

- Sassoon, Adrian, and Gillian Wilson. Decorative Arts: A Handbook of the Collections of the J. Paul Getty Museum. Malibu, CA: J. Paul Getty Museum, 1986.

- Verlet 1966

- Verlet, Pierre. La maison du XVIIIe siècle en France: Société, décoration, mobilier. Paris: Baschet, 1966.

- Wilmering 1999

- Wilmering, Antoine M. Italian Renaissance Intarsia and the Conservation of the Gubbio Studiolo. New York: Metropolitan Museum of Art, 1999.

- Wilson and Hess 2001

- Wilson, Gillian, and Catherine Hess. Summary Catalogue of European Decorative Arts in the J. Paul Getty Museum. Los Angeles: J. Paul Getty Museum, 2001.